In today’s fast-paced world of transportation and logistics, the demand for efficient hauling solutions is growing across multiple sectors. One tool that consistently meets that demand is the flatbed trailer.

Many flatbed trailer industries rely on these versatile platforms to transport oversized, heavy, or oddly shaped cargo that doesn’t fit into standard enclosed trailers. Whether it’s construction materials, farming equipment, or industrial machinery, flatbed trailers make the job easier, faster, and safer.

Unlike closed box trailers, flatbeds don’t have walls or a roof, allowing for easy side and top loading. That’s why businesses that require flexible hauling options often turn to flatbeds as their go-to solution.

If you’re wondering which sectors depend on flatbed trailers the most—and why—this guide will walk you through the top 5 flatbed trailer industries, the benefits of flatbed hauling, and how to choose the right trailer for your work.

What Is a Flatbed Trailer?

A flatbed trailer is a type of open-deck trailer with no sides or roof. It’s designed to haul items that are large, tall, wide, or shaped in a way that makes enclosed trailers impractical.

Because of its open design, a flatbed trailer can be loaded from the sides, rear, or top, making it incredibly versatile. This is especially helpful for cargo like steel beams, lumber, heavy equipment, or agricultural supplies.

One of the biggest advantages of flatbeds is that they support heavy-duty tie-downs, chains, and tarps. This keeps loads secure during long-distance hauls—even over rough terrain or through poor weather.

Why Are Flatbed Trailers So Popular?

Here are a few reasons why industries consistently choose flatbeds trailers over enclosed models:

- No size restrictions (within legal limits)

- Easy access for forklifts, cranes, and loaders

- Perfect for irregularly shaped or bulky cargo

- Used across multiple industries, from construction to agriculture

To put it simply, flatbed trailers are the workhorses of the hauling world. Their adaptability is what makes them a must-have asset in so many sectors.

Why Flatbed Trailers Are Essential in Certain Industries?

Flatbed trailers are an essential type of equipment used across various industries due to their open design, high load capacity, and ease of loading and unloading. Unlike enclosed trailers, flatbeds don’t have sides or a roof, making them ideal for transporting oversized or irregularly shaped goods that wouldn’t fit in a standard trailer. Below is a detailed explanation of why flatbed trailers are vital in specific industries:

1. Construction Industry

Why Flatbeds Matter?

- Transporting oversized materials like steel beams, concrete forms, lumber, scaffolding, and prefabricated walls requires open and accessible trailer space.

- Many construction items are irregularly shaped or too long for enclosed trailers (e.g., rebar bundles, pipes, trusses).

- Flatbeds allow loading from all sides via forklifts or cranes, making it easy to load heavy or awkward materials directly from the construction site or warehouse.

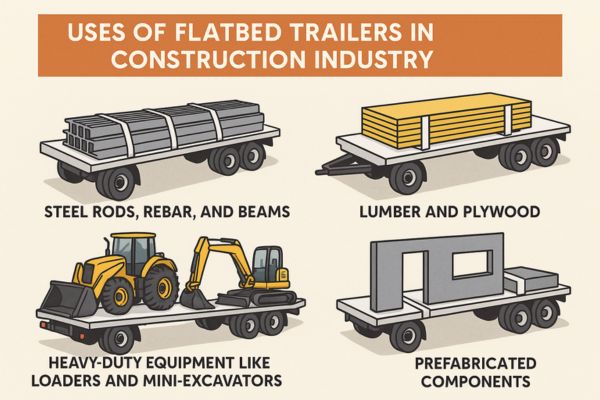

Common Construction Cargo:

- Steel rods, rebar, and beams

- Lumber and plywood

- Heavy-duty equipment like loaders and mini-excavators

- Prefabricated components

2. Agriculture and Farming

Why Flatbeds Matter?

- Farms frequently need to move large machinery like tractors, seeders, harvesters, and tillers that can’t fit into enclosed trailers.

- During planting and harvesting seasons, large volumes of produce, hay bales, or feed must be transported quickly and efficiently.

- Farmers benefit from the easy access and flexibility flatbeds offer, especially when loading on uneven rural terrain.

Common Agricultural Cargo:

- Baled hay and straw

- Tractors and combines

- Irrigation equipment

- Fencing supplies

3. Manufacturing and Heavy Equipment

Why Flatbeds Matter?

- Heavy manufacturing operations produce large, industrial components like generators, boilers, or machine frames that are often too wide or tall for enclosed trailers.

- Flatbeds are crucial for moving finished products to assembly plants or distribution centers.

- They are ideal for oversized loads that require special permits and escorts, often seen in the transport of fabricated steel or factory equipment.

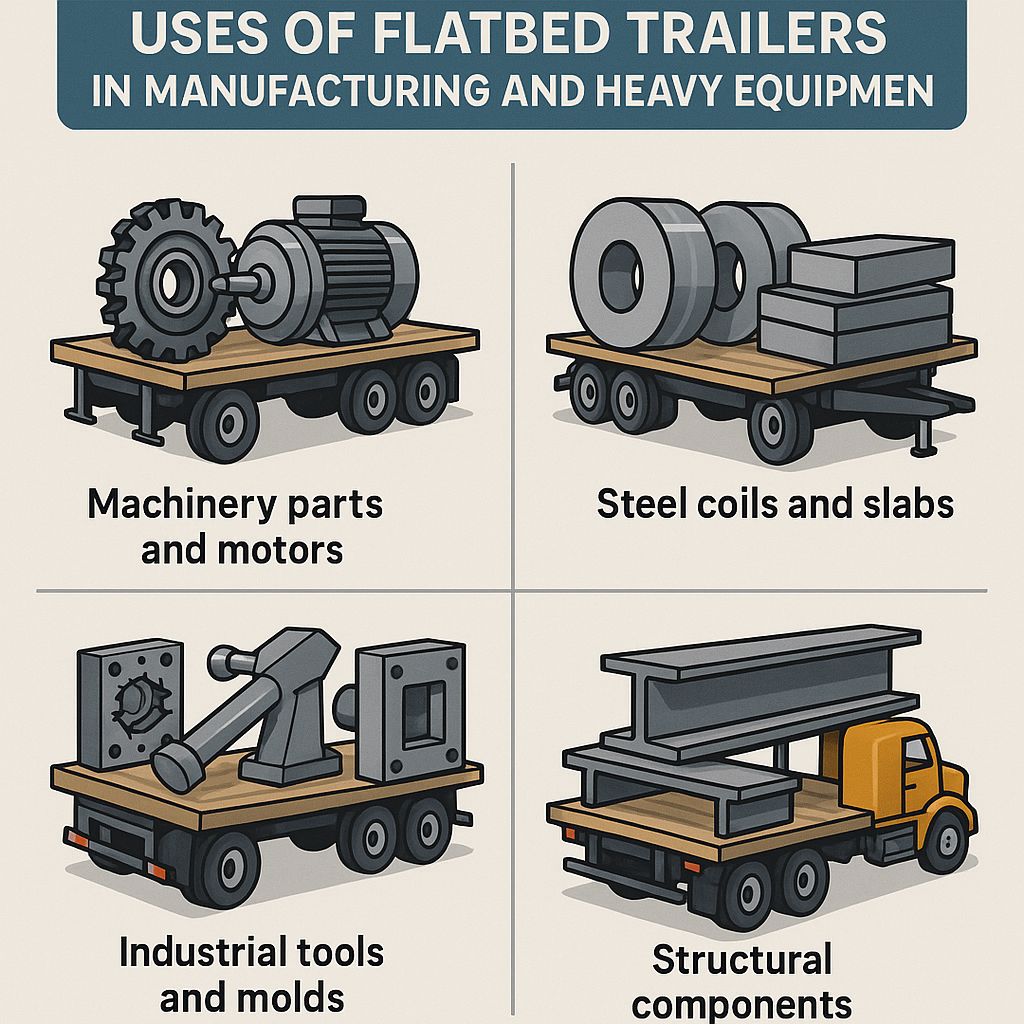

Common Manufacturing Cargo:

- Machinery parts and motors

- Steel coils and slabs

- Industrial tools and molds

- Structural components

4. Oil and Gas Industry

Why Flatbeds Matter?

- This industry operates in remote and rugged environments, requiring transportation of drilling rigs, pipe sections, fuel tanks, and equipment skids.

- Flatbeds are perfect for modular and heavy equipment that must be moved between drilling or production sites.

- Time-sensitive operations demand quick loading and unloading, which flatbeds enable without complex maneuvering.

Common Oil & Gas Cargo:

- Drill pipes and casing

- Generators and fuel tanks

- Modular site offices or shelters

- Compressors and pumps

5. Freight and Logistics

Why Flatbeds Matter?

- Freight companies use flatbeds to move non-standard freight that doesn’t require enclosure, like palletized goods, lumber, or construction materials.

- They are often used in LTL (Less-than-Truckload) shipping when a company has odd-sized freight or when quick loading/unloading is needed.

- Flatbed trailers support time-sensitive or specialized delivery needs across regional and national logistics networks.

Common Freight Cargo:

- Building supplies

- Industrial containers

- Machinery and tools

- Crated freight

Key Benefits of Using Flatbed Trailers in These Industries

It’s easy to see why so many flatbed trailer industries count on these trailers day in and day out. Beyond their flexibility, flatbeds offer several real-world benefits that make them invaluable for both short hauls and long-distance freight.

Here are five of the most important benefits:

1. Maximum Flexibility

Flatbed trailers aren’t confined by walls or ceilings, which means they can haul just about anything—steel pipes, lumber, tanks, equipment—you name it. This makes them incredibly useful in industries like construction, agriculture, and manufacturing, where cargo often doesn’t come in standard sizes.

2. Easier and Faster Loading

Unlike enclosed trailers that require back-end loading only, flatbeds allow for side and top access. This makes it quicker and easier to load large or heavy items using cranes or forklifts. Industries working on tight deadlines—such as freight and logistics—greatly benefit from this.

3. Cost Efficiency

Flatbeds help reduce transportation costs by allowing larger, more irregular loads to be delivered in fewer trips. That means less fuel, fewer labor hours, and faster project timelines—especially in heavy equipment industries like oil and gas or construction.

4. Wide Range of Trailer Options

There’s a wide selection of flatbed types available—standard, step deck, extendable, and more. This range allows businesses to customize their trailers based on load requirements, which is why flatbed trailer industries often invest in multiple trailer types for specific needs.

5. No Loading Dock Needed

In rural or undeveloped areas where docks aren’t available, flatbed trailers shine. They can be loaded or unloaded directly on-site, which is vital for agricultural and energy sectors working off the grid.

Choosing the Right Flatbed Trailer for Your Industry

Not all flatbed trailers are created equal. Choosing the right one depends heavily on what your business moves and how often it moves it. Here’s a guide to help narrow down your options:

1. Understand Your Cargo

Before investing, make a list of the common loads your company hauls. Are they wide, tall, or extremely heavy? Flatbeds are excellent for oversized loads, but you may need a step deck trailer for taller items or an extendable flatbed for long machinery.

2. Match the Trailer to the Industry

Different flatbed trailer industries have different needs:

- Construction may need rugged frames and high weight capacity.

- Farming might require shorter trailers for tight turns on rural roads.

- Manufacturing and logistics may benefit from drop decks or tandem axle setups.

3. Consider Legal Limits

Each trailer must comply with federal and local regulations for load weight and size. Exceeding legal limits could mean heavy fines or even losing your license. That’s why it’s crucial to check GVWR (Gross Vehicle Weight Rating) and ensure it matches your typical haul.

4. Think About Maintenance and Durability

If your trailer will be used in tough conditions—such as oil fields or remote farms—you’ll want one that’s built for durability. Look for corrosion-resistant materials, reinforced decks, and heavy-duty axles.

Conclusion

Flatbed trailers have earned their place as a vital asset in industries that rely on power, performance, and practicality. From transporting heavy-duty construction gear to moving oversized farming equipment, these trailers are the unsung heroes of logistics and freight.

If you work in construction, agriculture, energy, or freight, chances are your company already depends on a flatbed—or should. The unmatched flexibility, easy loading, and cost-saving potential explain why flatbed trailer industries continue to grow and innovate around these versatile tools.

Whether you’re upgrading your current fleet or just getting started, understanding how flatbeds fit into your business can make a big difference in your bottom line.

Ready to Power Up Your Haul? At Phoenix Trailer Depot, we don’t just sell trailers, we help you move your business forward.

FAQs: About Flatbed Trailers and Their Industry Uses

1. What makes flatbed trailers different from enclosed trailers?

The biggest difference is openness. Flatbed trailers have no sides or roof, which means you can load cargo from the sides, top, or rear. That makes them perfect for transporting items that are too wide or tall for enclosed trailers. In flatbed trailer industries like construction and manufacturing, this open design is a game-changer for hauling irregular loads like steel beams, pipes, or machinery.

2. What types of industries rely most on flatbed trailers?

Flatbed trailers are vital in multiple sectors, including:

1. Construction – For hauling steel, lumber, and equipment

2. Agriculture – For transporting hay, tractors, and feed

3. Manufacturing – For moving raw materials and heavy parts

4. Oil & Gas – For delivering large components to remote sites

5. Freight and Logistics – For versatile, on-demand deliveries

Each of these flatbed trailer industries relies on flatbeds for their adaptability and ease of access.

3. Do flatbed trailers require special permits for oversized loads?

Yes, they can. While flatbed trailers allow for large and wide cargo, each state has legal load limits for height, weight, and width. If your load exceeds those limits, you’ll need an oversize load permit. Some states may also require escort vehicles or specific routing.

It’s best to check your local DOT (Department of Transportation) or use a logistics service to manage the permit process. You can also read up on oversize load regulations via FHWA.gov.

4. How do I secure loads on a flatbed trailer safely?

Proper load securement is critical in all flatbed trailer industries. Use a combination of:

1. Heavy-duty straps or chains

2. Corner protectors

3. Load binders

4. Tarps (for weather protection)

Make sure to follow the FMCSA’s cargo securement rules to avoid accidents and fines. Each type of cargo has specific requirements, so always use the right tools for the job.

5. What should I look for when buying a flatbed trailer for my business?

Here are a few tips:

1. Payload Capacity: Choose a trailer that can handle your heaviest loads.

2. Deck Length and Material: Make sure it’s long enough and built from durable materials like steel or aluminum.

3. Axle Configuration: Tandem or tri-axles work better for heavier equipment.

4. Trailer Type: Gooseneck, step-deck, or extendable—match the type to your industry’s needs.

Leave a Reply